Introduction:-

HAZARD IDENTIFICATION & RISK

ASSESSMENT (HIRA)

A Hazard Identification and Risk Assessment (HIRA) assists emergency

managers in answering these questions. It is a

systematic risk assessment tool that

can be used to assess the risks of various hazards.

JOB SAFETY ANALYSIS ASSESSMENT (JSA):-

HIRA:-

There are three reasons why a HIRA is useful to the emergency management profession:

· It helps emergency management professionals prepare for the worst

and/or most likely

risks.

·

Allows for the creation

of exercises, training

programs, and plans

based on the most

likely scenarios.

·

Saves time and resources

by isolating hazards that cannot occur in the designated

area.

Risk is the unwanted consequence of an event or series

of events. Risk occurs when multiple

risk causing factors occur at the same time causing

an accident manifesting in an

event like a fire or explosion. Risk Assessment (RA) is a method that has

proven its value as an all-round

tool for improving

the safety standards prevalent in every hazardous industry.

With advancements in in-built and inherent safety

systems, accidents rates have come down, but still persist

at unacceptable levels for newer technology, new plants and chemical handling

facilities. RA is a structured safety assessment

tools designed for high hazard industries such as chemical, petrochemical, pesticides, pharmaceuticals, sea ports,

etc., supplementing other safety systems tools such as HAZOP, safety audit, and regular incident

analysis to identify

the potential for incidents (near-misses, unsafe conditions) and to evaluate

the necessary control

measures.

Objectives of HIRA study:

- Identify the existing safeguards available to control the risks due to the hazards.

- Suggest additional control measures to reduce the risk to an acceptable level.

·

Prepare a Risk register that will help in continuously monitoring

these risks, detect

any changes and ensure the controls are effective.

Steps involved in Hazard identification and risk assessment:

Step 1: Identification of the Hazard.

Hazard Identification is a critical step in Risk Analysis. Many aids are available, including experience, engineering codes, checklists, detailed process knowledge, equipment failure experience, hazard index techniques, What-if Analysis, Hazard and Operability (HAZOP) Studies, Failure Mode and Effects Analysis (FMEA), and Preliminary Hazard Analysis (PHA). In this phase all potential incidents are identified and tabulated. Site visit and study of operations and documents like drawings, process write-up etc are used for hazard identification.

Step 2: Assessment of the Risk:-

Consequence Estimation is the methodology used to determine the potential for damage or injury from specific incidents. A single incident can have many distinct incident outcomes. Likelihood assessment is the methodology used to estimate the frequency or probability of occurrence of an incident. Estimates may be obtained from historical incident data on failure frequencies or from failure sequence models, such as fault trees and event trees. Risks arising from the hazards are evaluated for its tolerability to personnel, the facility and the environment. The acceptability of the estimated risk must then be judged based upon criteria appropriate to the particular situation.

Step 3: Elimination or Reduction of the Risk

This involves identifying opportunities to reduce the

likelihood and/or consequence of an accident Where deemed to be necessary. Risk Assessment combines the consequences and likelihood of all incident

outcomes from all selected incidents

to provide a measure of risk. The risk of all selected

incidents are individually estimated and summed

to give an overall measure of risk.

Risk-reduction measures include those to prevent incidents (i.e. reduce the likelihood of occurrence) to control incidents

(i.e. limit the extent and duration

of a hazardous event) and to mitigate the effects (i.e. reduce the

consequences). Preventive measures,

such as using inherently safer designs and ensuring asset integrity, should be used wherever practicable. In

many cases, the measures to control and mitigate hazards and risks are simple and obvious

and involve modifications to conform to standard

practice.

The general hierarchy of risk reducing

measures is:

· Prevention (by distance or design)

· Detection (e.g. fire and gas, Leak detection)

· Control (e.g. emergency shutdown

and controlled depressurization)

· Mitigation (e.g. fire fighting and passive fire protection)

· Emergency response

(in case safety barriers fail)

Components of Risk Assessment:

The normal components of a risk assessment study are:

Ø Hazard identification and specification

Ø Risk Review

Ø Recommendations on mitigation measures

Failure case identification

The first stage in any risk assessment study is to identify the potential accidents

that could result

in the release of the hazardous material

from its normal

containment.

Chemical hazards are generally considered to be of three types:

·

Flammable

·

Reactive

·

Toxic

Where there is the potential for confined gas releases, there is also the potential

for explosions. These often produce

overpressures which can cause fatalities, both through direct action on the body or through

building damage. Potential

accidents associated with any

plant, section of a terminal/plant or pipeline can be divided into two categories:

·

There is a possibility of failure

associated with each, mechanical component of the facility/terminal (vessels, pipes, pumps or compressors). There

are generic failures and can be

caused by such mechanisms as corrosion, vibration or external impact (mechanical or overpressure). A small event (such as a leak) may escalate

to a bigger event, by itself causing

a larger failure.

·

There is also

a

likelihood of

failures caused

by

specific operating

circumstances. The prime

example of this is human

error, however it can also include other

accidents due, for example, to reaction runaway

or the possibility of ignition

of leaking tank gases due to hot work.

Classification of Major

Hazard Units:

- ·

Damage of oil storage tanks

and oil leaks into the sea

- ·

In case of fire explosion

- ·

In case of emergency during

ship maneuvering

- ·

In case of vessel or boat collision

Hazard Identification

Identification of hazards

in the proposed jetty is of primary

significance in the analysis, quantification and cost effective control of accidents and process.

Definition of hazard states that,

hazard is in fact the characteristic of system/process that presents potential for an accident. Hence, all the

components of a system need to be thoroughly

examined to assess their potential

for initiating or propagating an unplanned event/sequence of events, which can be termed as an accident.

The following two methods for hazard identification have been employed

in the proposed Jetty Study:

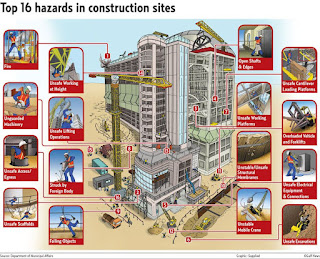

Hazards during Construction Phase

- ·

Mechanical Hazards

- ·

Transportation Hazards

- ·

Physical Hazards

- ·

Storage and Handling

of Hazardous Materials

Hazards during Operation Phase

·

Material Hazards

·

Handling Hazards

Hazards due to Natural

Calamities

·

Earthquake

·

Tsunami

·

Cyclone/Flood

Hazards during Construction Phase

Potential hazards during the construction phase of the project could be due to the mechanical

hazards, navigation/ transportation hazards, physical hazards and storage and handling

of hazardous materials.

Mechanical

Hazards: Mechanical hazards during the construction

phase arise due to the moving parts in the machinery, especially the belts and bolts of the construction equipment, which are heavy

and pose a threat to the work personnel. Other hazards include

falling (during working

at heights), falling

objects like hand held tools,

etc; failure of slips and traps created

for scaffolding; and due to faulting of electrical equipment.

Navigation/

transportation Hazards: Planning of access/egress

to construction site also plays significant role in minimizing the associated hazards

such as vehicles/ barges collision.

Physical Hazards:

The noise and vibrations generated during

construction phase may affect the workers health,

hinder effective communication. In addition to noise and vibration,

hot works also pose a considerable hazard to

the workers.

Hazards during Operational phase

Material Hazards: During operation, Liquid Cargo will be handled

at the proposed facility. The

Liquid cargo hazard classification can be made based on its Characteristics such as Flammability, explosiveness, toxicity or corrosivity etc.

Handling Hazards:

Proposed jetty involves

handling of Liquid Cargo. The hazards related

to edible oil transport and unloading may be due to accidents, breaking of unloading

arms, failure in mechanical components, etc. The handling

hazards include:

·

Insufficient knowledge on hazardous

nature of Liquid Cargo in use leading to inappropriate handling

of the Liquid Cargo.

·

Failure to use appropriate control

measures and Personal Protective Equipment (PPE)

·

Use of expired/worn Personal Protective Equipment’s (PPE’s)

· Failure of liquid delivery

tools.

· Possible hazards

during ship movements

at the port are collision,

grounding, etc.

· Likely hazards during loading

and unloading of Liquid Cargo.

·

During ship unloading operations,

the possible hazard may arise

due to collision by another vessel and

others.

Cargo handling: A fully mechanized ship loading/unloading system

(Pipelines) is planned at the berths. The major

components of the mechanized ship loading/unloading system are Pumps and Pipelines.

Ship

movements/Navigation Hazards: The navigation

hazards during operation phase are

grounding and collision of vessels. However, these would be controlled by

suitable vessel traffic

management.

Ship unloading: During ship unloading operations, possible hazard may arise due to collision

by another vessel and

others.

Transfer

operation: The transfer operation involves transfer

of liquid cargo from ships through

pipelines. During this operation there is a possibility of mal-operation / non- synchronization / misalignment leading to liquid cargo spillage.

Slip and Trip

Hazards: Workers performing cleaning operations are

exposed to slippery working surfaces and tripping hazards.

This places workers

at risk of:

·

Slipping off oily and greasy ladders

·

Slipping and falling

on oily decks

·

Tripping over equipment, hoses and vessel structures

Hazard due to Natural Calamities:

Cyclone, Tsunami and Storm surge are the most

destructive forces among the natural devastations. It causes instant

disaster and burial

of lives and destruction to entire coastal

properties. The damage

and loss can be minimized

if appropriate preparedness plan is formulated. The following statutory guidelines are recommended by National

|

Types of Disasters |

Risk incurred |

Mitigation steps |

|

Earthquake |

Highest vulnerability towards

earthquake occurrence (based

on past history) resulting into massive

destruction. |

Structure proposed should

comply as per relevant IS Codes

for Earthquake resistant structures for adequate factor of safety. |

|

Tsunami |

Kandla region had been affected by Tsunami in past with a

ht. of 12m in 1945.

Thus, it is also one

of the major risks applied

to the SIPC locations. |

Land use planning should be as per the zoning maps by Gujarat State Disaster Management Authority (GSDMA) |

|

Cyclone |

Gujarat falls in the region

of tropical cyclone

and is highly

vulnerable to associated hazards such as floods,

storm surges etc. Kandla falls

in the belt in which

the wind speed

ranges between 45-47m/sec. Over 120 cyclones originated within Arabian

Sea in past 100 years. Damage to property and life is huge. |

Structure proposed should

comply as per relevant IS Codes for cyclone resistant structures for adequate factor of safety. |

|

Drought |

Kandla is a drought prone area with

less rainfall Drought vulnerability increases the groundwater exploitation |

Rain water harvesting should be mandatory |

|

Epidemics |

Outbreak of Epidemics such as swine

flu has been seen in past |

Necessary steps should

be undertaken to have hygienic conditions and medical

assistance within the location to cater to any epidemic |

A Risk Analysis should therefore, be seen as an

important component of any or all on- going

preventive actions aimed at minimizing and thus hopefully, avoiding accidents.

Re- assessments should therefore

follow at regular intervals, and/or after any changes that could alter

the hazard, so contributing to the overall prevention programme and disaster management plan of the project.

Please click on the below link and download all HIRA /JSA

1. Working at height- DOWNLOAD

2. All Activity HIRA- DOWNLOAD

3. All Activity JSA- DOWNLOAD

0 Comments

If Yiu have Any doubts, Please let me know